Max phasethe next generation material for advanced application

Introduction to MAX Phase

The demand for advanced materials with superior properties has been increasing rapidly in the fields of aerospace, automotive, energy, and electronics. In recent years, MAX phase materials have emerged as a promising candidate for various high-performance applications. MAX phases are a family of layered ternary compounds, where “M” stands for a transition metal, “A” for an A-group element, and “X” for carbon or nitrogen. These materials exhibit a unique combination of metallic and ceramic properties, making them suitable for a wide range of industrial and technological applications.

Structure and Properties

MAX phases possess a layered crystal structure, with strong covalent M-X bonding within the layers and weaker metallic M-A bonding between the layers. This unique structure gives rise to exceptional mechanical, thermal, and electrical properties. MAX phases are characterized by high thermal conductivity, excellent damage tolerance, oxidation resistance, and good electrical conductivity. These properties make them attractive for use in extreme environments where traditional materials may fail.

![]()

Applications in Aerospace

In the aerospace industry, the demand for lightweight, high-temperature materials is ever-present. MAX phases have garnered significant interest for their potential use in aerospace components such as turbine blades, heat shields, and structural materials. Their combination of high-temperature stability, low density, and good mechanical properties makes them an excellent candidate for next-generation aerospace materials. Additionally, their resistance to oxidation and thermal shock further enhances their suitability for aerospace applications.

Automotive Industry

The automotive industry has also recognized the potential of MAX phase materials in improving vehicle performance and efficiency. As the industry shifts towards electric vehicles and the demand for high-performance batteries increases, MAX phases are being explored for use in battery electrodes and current collectors. Their excellent electrical conductivity and thermal stability make them ideal for enhancing the efficiency and longevity of next-generation automotive batteries.

![]()

Energy Sector

In the energy sector, there is a growing need for materials that can withstand harsh operating conditions in power generation and renewable energy systems. MAX phases offer excellent potential for use in high-temperature coatings, heat exchangers, and nuclear fuel cladding due to their thermal stability and corrosion resistance. Furthermore, their ability to maintain mechanical integrity at elevated temperatures makes them valuable for next-generation energy applications.

Electronics and Semiconductors

The electronics industry continually seeks materials with enhanced thermal management and electrical properties. MAX phases have shown promise in this regard, with potential applications in electronic packaging, thermal interface materials, and high-power electronic devices. Their high thermal conductivity and electrical resistivity make them attractive for improving the performance and reliability of electronic and semiconductor devices, especially as the demand for miniaturization and higher power densities continues to rise.

![]()

Challenges and Future Outlook

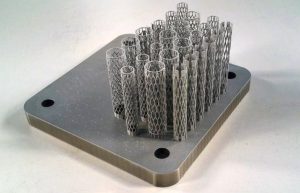

While the potential of MAX phase materials is undeniable, several challenges must be addressed to facilitate their widespread adoption. One major hurdle is the scalability of production methods to ensure cost-effective manufacturing of bulk components. Additionally, further research is needed to optimize the microstructure and properties of MAX phases for specific applications, as well as to develop novel processing techniques that enable the fabrication of complex shapes and structures.

Looking ahead, the continued research and development efforts in the field of MAX phases hold great promise for unlocking their full potential across diverse industries. Collaborative initiatives between academia, industry, and government agencies will be essential to push the boundaries of MAX phase technology and accelerate its integration into commercial products. Moreover, the exploration of advanced synthesis and processing routes will play a crucial role in expanding the application scope of MAX phases and realizing their role as a cornerstone of the next generation of advanced materials.

In conclusion, MAX phase materials represent a compelling class of materials with unparalleled properties that position them as a game-changer for a wide array of advanced applications. As research and innovation in this field progress, MAX phases are poised to revolutionize the landscape of materials science and engineering, driving progress in aerospace, automotive, energy, electronics, and beyond. With their unique combination of characteristics, MAX phases are set to shape the future of advanced materials and pave the way for transformative technological advancements.

What is copper-nickel made of b1265

.webp)